In manufacturing, chaos often hides behind efficiency. Orders get approved before specs are finalized. Customer details get stuck in spreadsheets. Sales promises don’t always reach the production floor.

That gap costs time, trust, and revenue: and it widens as the business scales.

A modern CRM for manufacturing companies closes that gap. It connects people and processes that rarely speak the same language: sales, marketing, production, and support. The result is a clear picture of every customer and every order, from quote to delivery.

In this guide, we’ll look at the top CRMs that help manufacturers stay organized and agile.

What makes a great CRM for manufacturing?

A single miscommunication can stall production or delay a shipment in the manufacturing industry. When quotes and client updates live in separate places, teams lose time hunting for answers instead of keeping work on track. A manufacturing CRM solves that by connecting the moving parts of sales and production in one view.

The most effective systems do more than store customer information. They help teams plan, act, and adapt as conditions change.

Look for features such as:

- Central workspace for client and order data: reduces errors and keeps teams aligned. Order history and communication records stay in one place, making it easier to maintain consistent relationships and win repeat business.

- Links with quoting and stock tools: unite everyday operations with accurate customer records. Quotes that convert into orders update invoicing and inventory automatically, so manufacturers always know what’s moving through the pipeline.

- Reliable sales forecasting: improves production planning and inventory control. Insights into customer behavior help manufacturing leaders anticipate demand shifts and prevent both shortages and excess stock.

- Built-in sales automation: cuts routine admin by triggering follow-ups and task reminders at the right time. The sales team can focus on active deals instead of manual updates.

- Mobile access: gives the sales team full visibility while meeting clients or suppliers. Quick access to customer data on a phone or tablet turns field visits into faster decisions.

A strong manufacturing CRM also supports supply chain management, giving leaders visibility across processes and helping them react faster when priorities shift.

Best CRM software for manufacturers

Manufacturers can turn their long sales cycles into smoother operations by choosing a solid CRM platform. With the right tool in place, you can track potential customers more effectively, reduce repetitive tasks, access detailed reports, and ultimately drive product sales.

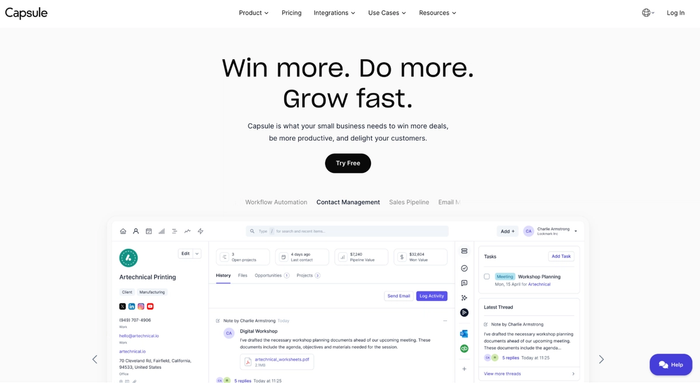

Capsule CRM – best manufacturing CRM

Manufacturing runs on precision, not only on the production floor but across every interaction with customers. A delayed update or missed quote can ripple through the entire supply chain.

That’s where Capsule CRM proves its worth.

It gives manufacturers a single place to manage sales, client relationships, and operational data without disrupting what already works.

For many companies, the biggest challenge is maintaining visibility once orders leave the workshop.

With Capsule, it's solved.

Customer information, order details, and communication history are accessible in one workspace, so every department sees the same version. When a client requests a modification to a quote, the sales team can update it instantly, and production managers can adjust schedules before materials go to waste.

Manufacturing leaders also value the clarity that comes from Capsule’s analytics. Instead of relying on spreadsheets or manual reports, managers can see which customers bring the most repeat business, how long deals take to close, and what trends point to future demand. That visibility turns daily data into better planning decisions.

Integrations are another strength. Capsule connects with tools already familiar to manufacturing teams: from accounting systems like QuickBooks and Xero to communication and quoting tools such as Zendesk, Yay, and Quotient. This means invoicing and stock updates move automatically, reducing human error and administrative drag.

Despite its depth, Capsule is lightweight. Setup takes hours, and the interface is straightforward enough that teams adopt it quickly, often without formal CRM training. As production and sales grow, plans scale easily, giving smaller manufacturers room to expand without moving to an entirely new system later.

Even for field teams, Capsule stays useful. Its mobile access lets sales reps pull up order histories or client notes while visiting a distributor, then update outcomes on the spot. Those changes sync immediately, keeping the entire operation aligned.

For manufacturers, that blend of speed, insight, and reliability is what makes Capsule CRM stand out.

It’s not just another tool to track customers. It’s a practical system that supports the real flow of manufacturing work, helping teams stay connected from the first quote to the final delivery.

Try Capsule CRM free for 14 days — no credit card required.

[CTA]

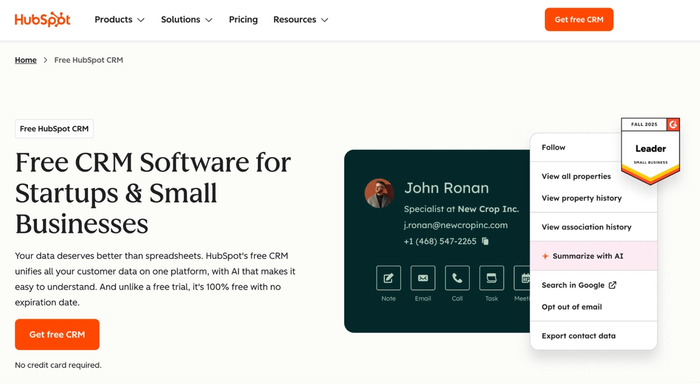

HubSpot CRM

If your manufacturing business combines strong lead-gen efforts with complex production flows, HubSpot CRM offers a unified platform built to support both.

HubSpot brings together sales, service, and marketing tools so your teams can manage customer relationships in one place. For manufacturers running inbound and outbound campaigns, this means you can capture leads via forms, nurture them with automated email workflows, and then push qualified opportunities into your manufacturing CRM software pipeline. Reviews highlight how its automation and form-building features make tracking what drives customer behaviour easier and help boost sales performance.

That said, there are considerations.

While many manufacturing leaders value the integrated approach, some users find that as the number of contacts, automation workflows, and custom reporting needs grow, the cost and complexity increase significantly. One review notes that “prices can add up quickly when you scale your business”.

Implementation can also require more resources, particularly if you’re mapping manufacturing processes and supply chain workflows into the system. There’s a risk that without a defined strategy, your teams will spend time configuring instead of delivering value.

When it comes to pricing, HubSpot offers an entry-level free CRM version and starter tiers, which are attractive for smaller teams. However, for more advanced features (such as workflow automation, advanced analytics, and full marketing hub capabilities) you’re looking at significantly higher tiers. Estimates point to costs starting in the low hundreds per seat/month and rising into thousands, especially when factoring in onboarding, integrations, and additional users.

Zoho CRM

For manufacturers managing complex approval chains and variable production schedules, Zoho CRM offers the flexibility to mirror real-world workflows and capture meaningful sales data.

Designed to support full customer-facing and operational cycles, Zoho CRM can map multi-step production or vendor management processes with custom modules and dashboards.

For example, a manufacturer can set up a pipeline where a quote moves from sales → engineering review → materials procurement → production scheduling → delivery, all within the same CRM. The system integrates with tools like Zoho Inventory and Zoho Books so that stock updates, invoicing, and order fulfilment reflect the same status seen in the CRM.

Customer inquiries, supplier updates, and internal approvals all connect in one place, improving responsiveness and transparency.

The platform’s strength in customization comes with a trade-off.

Several reviews note that while the depth of features is strong, smaller teams or those without dedicated admin support may face a steeper learning curve when tailoring workflows and modules. For instance, users appreciated how flexible the system is, but also commented that “the interface can feel cluttered” and setup takes time.

In a manufacturing context, this means that to capture full value (e.g., accurate tracking of production schedules, customer relationships, and sales process stages) you’ll want someone able to define those custom fields and actions.

Zoho CRM pricing begins with affordable tiers and scales upward as you add users, advanced reporting, or AI-driven features. Entry-level plans are cost-effective, yet the more advanced custom modules or deep integration options may push the cost into a more significant investment.

Pipedrive CRM

Pipedrive CRM is designed for teams that prioritise tracking deals with clarity and simplicity, especially useful in manufacturing environments where the sales process needs to stay transparent and actionable.

In practical use, Pipedrive stands out for its visual pipelines and straightforward automation. It gives manufacturing sales reps a clear interface where they can manage quotes, orders, and renewals as discrete stages in a pipeline. That drag-and-drop board view means they can instantly see where a deal sits, what tasks remain, and which opportunities might slip through.

The platform also supports the automation of follow-ups and reminders, helping them spend more time closing deals and less time entering data. According to multiple reviews, this kind of approach helps teams that value a “sales-first” workflow rather than the broadest CRM system.

Even so, you’ll need to weigh a few drawbacks.

While Pipedrive excels at the sales process and deal tracking, it isn’t built with full project, inventory, or heavy production schedule management in mind. For example, manufacturing companies looking to link quoting, production schedules, and supply chain management together may find that Pipedrive lacks some of the deeper modules present in more expansive CRM systems. Reviewers note its marketing automation and support-team features are less advanced, and that the value can diminish when you try to shoehorn it into complex workflows.

On pricing, Pipedrive offers a tiered structure that reflects its sales-centric design. Entry-level plans start affordably and provide the core features you’ll need for organising deals and tracking performance.

But to unlock advanced reporting, multiple pipelines, full automation, and better support, you’ll need a higher tier. This means that as you scale or add more sophisticated requirements, the cost rises. Some users also flag that add-ons (for forms, campaigns or advanced integrations) may add up.

Salesforce

Salesforce CRM fits manufacturers running multiple facilities and indirect sales networks, offering structure across every stage of customer engagement.

Salesforce excels in automating complex processes and supporting sophisticated analytics. As a platform, it enables deep contact management and full lifecycle customer relationship management, bringing together marketing, sales, and service teams in one ecosystem.

In the manufacturing industry, Salesforce’s specialised Manufacturing Cloud lets you align opportunities with production forecasts, sync channels, and integrate with ERP systems to improve demand forecasting and downstream production schedules.

Its strong automation toolkit supports custom approvals, vendor-portal workflows, and partner-sales models: all part of a modern sales and marketing strategy built for scale. Myriad dashboards surface sales data and customer behaviour so you can optimise your sales performance and improve customer satisfaction.

While powerful, Salesforce can be demanding in other ways.

Setup and configuration often require dedicated teams or external partners, and manufacturing leaders frequently warn that without proper governance, the system can become fragmented. Reviews cite the higher cost of ownership is a barrier for smaller units within a manufacturing group. It may cover nearly every aspect of CRM and marketing processes, but your organisation must be ready for the effort required to get the full value.

On pricing and total cost of ownership, Salesforce’s model starts with base CRM licences but scales rapidly once you add advanced modules, industry-specific clouds, custom objects or ERP integrations. For example, Manufacturing Cloud itself carries pricing above standard CRM tiers for large enterprises.

Many manufacturing firms find they need to budget for consulting, training, and integration costs that exceed the licence fee, which is something to factor into your decision if you’re evaluating CRM platforms.

Conclusion

Choosing the right CRM for manufacturing isn’t about stacking every possible feature. It’s about delivering clarity in operations and maintaining a full customer journey view: from inquiry through order processing and onward.

With Capsule CRM, manufacturers gain a CRM built for those very realities. It supports long sales cycles, turns customer data into insight, and simplifies what often becomes manual chaos: all while helping build brand loyalty and drive meaningful customer success.

Try Capsule CRM free for 14 days and see how it simplifies customer management for your manufacturing business.

Frequently Asked Questions

Capsule enables you to design task-and-event sequences that trigger automatically when a quote is approved or an order moves to production. This means teams no longer rely on manual updates, and you can keep the process infinitely easier as you scale.

Yes! Capsule centralises contact details, opportunity records and production status so your sales team, operations managers and service staff all work from the same view. That unified handling of a company’s interactions helps you maintain consistent customer relationships.

For manufacturers your CRM system should manage quotes through to delivery, support production schedules, offer deep reporting on sales data, integrate with your ERP and help you nurture leads with timely follow-up. Capsule ticks these boxes by combining visual pipelines, custom fields, mobile access and integrations tailored to manufacturing.